How to Optimize STL Files for 3D Printing Success

Optimizing your STL file ensures a smooth printing process and superior results. Properly prepared files reduce printing errors and material waste, helping you achieve your desired outcome.

1. Check and Set Correct Scale

Always verify your file's dimensions and export in millimeters to maintain consistency and accuracy.

2. Ensure Adequate Wall Thickness

Walls thinner than your printer’s nozzle (typically around 0.4 mm) won't print well. Design thicker walls to guarantee strength and structural integrity.

3. Achieve Watertight Models

Make sure your model has no holes or gaps. All edges should be connected to avoid printing errors.

4. Optimize Orientation

The right orientation reduces support material and improves surface finish. Orient your model to minimize overhangs and maximize structural strength.

5. Simplify Geometry

Excessively detailed meshes can slow down printing and cause slicing errors. Simplify your geometry while maintaining essential details.

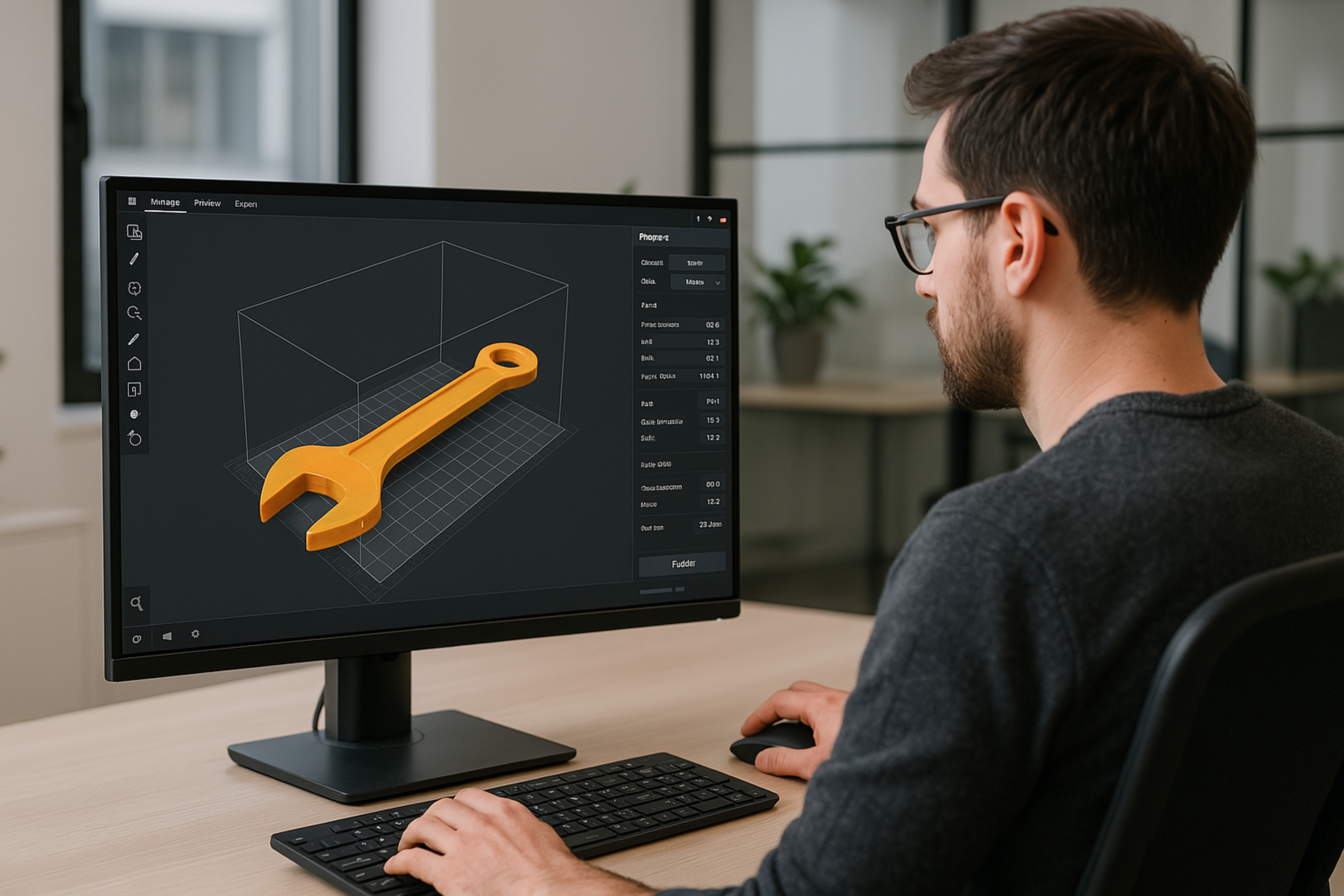

6. Utilize STL Repair Software

Programs like Netfabb, Meshmixer, and Lychee can identify and fix common STL errors automatically.

Did you know our instant quotation tool can even spot broken STL files? It’s like having a 3D printing detective on your team!

Submit your STL file today

Our instant quotation tool will help identify any errors, and with our guidelines, you’ll have your design ready for perfect printing!